Consider the Bending Angle: Not all angles are feasible with a few metals, as they will crack if bent as well considerably.

The overall length with the flat segment slightly decreases after the operations because the bent portion stretches some materials. Here, you must deduct some length to have the overall flat length, called bend deduction.

The benefit and time-efficiency made available from these advanced clamping solutions immediately translate to greater machine utilization, lessened lead situations, and improved responsiveness to buyer calls for within the aggressive sheet metal forming business.

The die and the punch used on the press brake the two have a significant influence on the bending success. They are a set designed in this kind of way that in the event the sheet metal is clamped concerning them it bends in the pre-determined designs and angles.

Mounted photoelectric guards encompass two sensors mounted in the extremities on the working zone, creating a protecting discipline that spans all the front location nearly 400mm with the machine.

How can producers ensure precision and performance in sheet metal bending? Picking out involving a press brake along with a CNC folder is very important. This post compares their working principles, bending precision,…

A controlled axis, or machine axis, refers to a certain movement on the machine that may be measured by an encoder and controlled by the pc by means of a motor or actuator.

As press brake technologies improvements, suppliers are producing significantly complex seal patterns to fulfill the calls for of better pressures, speedier cycle instances, and more complicated bending operations in present day sheet metal fabrication.

Sheet metal bending refers to deforming the flat metal sheet into a particular angle or curvature. It does not alter the thickness in the sheet.

Knowledge sheet metal bending is much more than simply technological know-how. Right here’s why it’s useful:

To mitigate alignment concerns, operators will have to perform a machine zeroing treatment utilizing the selected NC perform before initiating bending functions.

Focusing on a venture and need to bend and shape your metal into unique kinds without the need of getting the necessary machinery? Let's acquire away the guess do the job check here and get it done for yourself!

When sheet metal is manipulated from its original flat shape, its Bodily dimensions also are altered. The drive used inside the work will cause the fabric to compress and extend on The within and out of doors.

I am continuously considering, reading, and crafting about these subjects, consistently striving to stay on the forefront of my discipline. Allow my understanding and expertise be an asset to your company.

Tatyana Ali Then & Now!

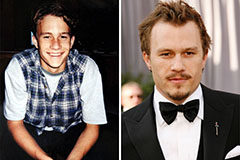

Tatyana Ali Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!